The lifting capacity of the magnet decreases substantially with the lifting conditions, hence,

lifting magnet must be selected after considering about the lifting conditions.

● Lifting Capacity

Maximum capacity is mentioned after considering safety factor. (1/3 for permanent magnet type, 1/2 for electromagnet type)

* Lifting capacity may decrease substantially depending on the lifting conditions. Hence,there may be cases when lifting magnet can not lift the mentioned weight capacity.

● Maximum Holding Power

Maximum holding power is found by contacting entire attractive face on a fixed ideal load without air gap and pulling up vertically until the magnet tears loose.

● Lifting Capacity

Maximum capacity is mentioned after considering safety factor. (1/3 for permanent magnet type, 1/2 for electromagnet type)

* Lifting capacity may decrease substantially depending on the lifting conditions. Hence,there may be cases when lifting magnet can not lift the mentioned weight capacity.

● Maximum Holding Power

Maximum holding power is found by contacting entire attractive face on a fixed ideal load without air gap and pulling up vertically until the magnet tears loose.

| Ideal Load |

| Material :SS400 or equivalent |

| Contact Surface : |

| Thickness :Thick enough |

●Lifting Conditions

Lifting capacity decreases substantially, depending on the above-mentioned conditions.

Please refer following graph and chart.

The holding power depends on the material and thickness of the load, condition of the contact surface (mill scale, cutting surface, grinding surface, etc),air gap between magnet and the load. Moreover, in case of electromagnet, it is also affected by the heat generation of the coil.

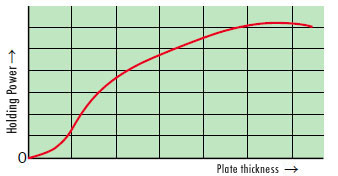

① Effect of Sheet Thickness on Holding Power

※The holding power decreases as the plate becomes thinner.

・As the size of magnet becomes smaller and/or pole pitch becomes smaller, comparatively the holding power to the thinner load increases.

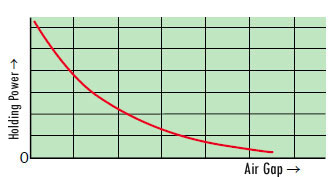

② Effect of Air Gap on Holding Power

※The holding power decreases with increase in air gap between magnet and the load.

・Air gap curtails the holding power substantially in case of compact electromagnets and permanent magnets.

③ Effect of Quality of Material on Holding Power

※SS400 is taken as standard for holding power

④ Effect of Surface Roughness on Holding Power

⑤ The Heat Generation of the Coil Reduces the Holding Power of Electromagnet.

The holding power at the time of coil being in cooled down stage is taken as maximum (100%).

As the magnetomotive force decreases due to heat generation at the time of coil energization, hence holding power also decreases.This reduction rate is generally about 10 to 20%, although it varies upon the operating time and size of the magnet.

The lifting magnet can be classified in 3 categories based on the magnet system, which are Permanent Lifting Magnet, Electromagnet Lifting Magnet and Electro Permanent Lifting Magnet.And based on shapes, it is round, rectangle and some special shapes.

As the lifting magnet is used for various purposes, please consult us for suitable magnet selection.

※Please inform the type of the load and use conditions as detail as possible when you order the magnet.